- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

- Home

- Product

- Applications

- Soulutions

- Company

- Services

- Information

- Contact

Views: 89 Author: Site Editor Publish Time: 2021-08-26 Origin: Site

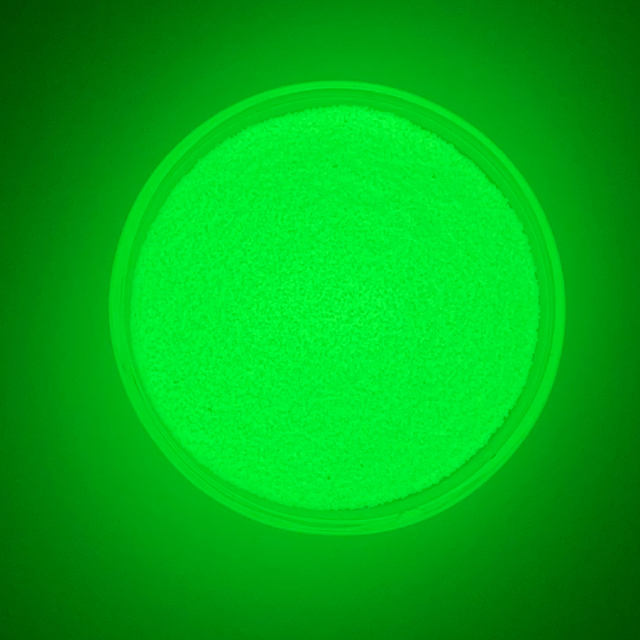

Glow powder stores the light energy after being irradiated by natural light, daylight light and ultraviolet light, and then releases it slowly after stopping light irradiation, so it can still be seen to glow at night or in the dark for a few hours to a dozen hours. This color-changing pigment, with a service life of up to 15 years, can absorb and release light in an infinite cycle. Glow powder will appear precipitation phenomenon in the process of use. I will talk with you, the reason of this situation and the treatment method.

Glow pigment appears precipitation, often two situations, one, because its specific gravity is larger, so in the glue, varnish, varnish and other liquids mixed use will appear precipitation phenomenon; two, long-term placement of glow powder will also be easy to appear precipitation.

For the first case, professional printing material manufacturers will recommend that consumers in the mix with other liquids, add anti-sink agent, while you can choose a finer glow powder, but need to pay attention to the glow powder is too fine glow brightness than the coarse powder, so choose carefully. If the phenomenon of precipitation caused by placing too long, just before use, available glass rod stirring can be used, you can also use diluent to adjust the viscosity, but can not use heavy metal compounds as additives.

The current market glow powderis an environmentally friendly printing materials, it is a powder photoluminescent luminescent material, through the absorption of various visible light to achieve glow function, especially for 450 nanometers below the short-wave visible light has a strong absorption capacity, and can be recycled many times. Topfan glow powder does not contain radioactive elements and can be evenly distributed in various transparent media such as coatings, inks, paints, plastics, printing pastes, ceramics, glass, fibers, etc. to achieve the glow function of the media.

Due to the glow material specific gravity is easy to precipitate, tuned into the ink coating before use need to be fully mixed evenly. To achieve good glow effect, try not to use too fine particle size of glow powder, the smaller the particle size of glow material, the weaker the glow brightness,? And printing base color to white and reflective color, can improve the brightness and glow time, such as adding fluorescent color as much as possible in the glow powder of less than 1%, the less fluorescent pigment on the brightness of the less impact.