- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

- Home

- Product

- Applications

- Soulutions

- Company

- Services

- Information

- Contact

Views: 114 Author: Site Editor Publish Time: 2021-11-02 Origin: Site

With the development of the economy, people's lives to well-off, the increasing number of high-rise buildings, the state is paying more and more attention to fire safety, the government fire department functions are constantly strengthened, "how to reduce casualties" is listed as one of the key fire work. When a fire accident occurs, the power is generally cut off and the building is in darkness, so the evacuation of people is a life-threatening matter. The "9.11 incident" that shocked the world was because of the use of these products, allowing many people to escape, greatly reducing casualties.

The application field of fire signs is very wide, such as buildings, hotels, stadiums, airports, underground passages, hospitals and other places need this kind of fire signs, the application of luminous signs in the country has a lot of room for development, many people still do not know and understand the product, so this article will introduce the product in detail.

1. PVC sheet is cut by paper cutter, which not only saves time, has neat edges, no burrs, and no scars on the board surface.

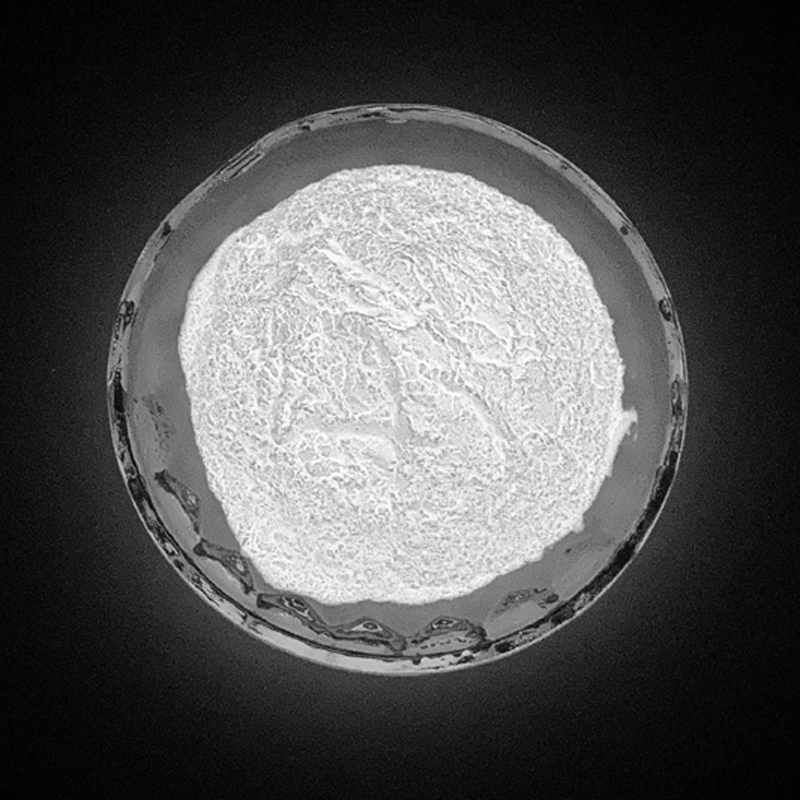

2 Before screen printing glow ink wigh pigments, you must first print a white plastic ink priming, and then screen printing covering luminous ink. Because white has a reflective effect, luminous brightness of 100.

3. In the printing found in the plastic ink dry easy to seal the plate, affecting the quality of printing, should add a slow drying agent blending use.

4. Whether printing white plastic ink or luminous ink, are to be scraped from a distance to the pocket, back to the ink from the pocket to the far side of the push, scraping direction should be the same consistent, covering the ink should be uniform.

5. Scrape printed on the PVC board how much ink, depending on the dynamic pressure of the scraper. Scraper hardness 70 ~ 75 °, the edges should be vertical and flat, the length of the scraper should be large out of both sides of the screen 2 ~ 3cm scraping angle, pressure and speed to master well on their own, and make the necessary adjustments in a timely manner.

6. printing finished products for the installation of aluminum alloy frame or plastic frame, the edges of the frame should be polished smooth, so as not to have a rough, cutting feeling, while attention should be paid to the frame clamping corners, not loose. After the installation is completed, it must be bagged immediately to avoid bringing harm to the surface of the signboard, and finally the qualified products will be boxed and put into storage.