- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

- Home

- Product

- Applications

- Soulutions

- Company

- Services

- Information

- Contact

Views: 74 Author: Site Editor Publish Time: 2021-07-13 Origin: Site

Powder coating is a kind of 100% solids coating, which has the characteristics of solvent-free, pollution-free, energy and resource-saving, low labor intensity and high mechanical strength of coating film. Since the world's first oil crisis in 1973, the powder coating industry has been developing rapidly, by 1980, the world's powder coating production has exceeded 74kt, 290kt in 1990, 520kt in 1995, and reached 700kt in 1999. The total sales revenue of powder coatings is expected to reach 5.78 billion US dollars by 2005. (At present, the fastest growth rate of powder coatings is 7% in the Asia-Pacific region.

And the largest proportion of powder coating production is Europe. According to the report of Science and Technology News, the domestic powder coating production reached 100kt in 2000, which has ranked the 3rd in the world. In recent years, China's powder coating production has been maintaining a double-digit growth rate.

At present, there are about 600 powder coating manufacturers in China, among which European and American companies have advantages in the Chinese market. Famous foreign powder coating manufacturers, such as DuPont, Akzo Nobel, Flow and other companies have established production bases in China. The competitive situation in the powder coating market in Guangdong and other coastal areas has been quite intense in the last two years. Powder coating manufacturers have started to turn to the mainland market in order to expand their sales and develop new markets, while solidifying their existing market share. The competitive situation in the domestic market will become more intense in the future.

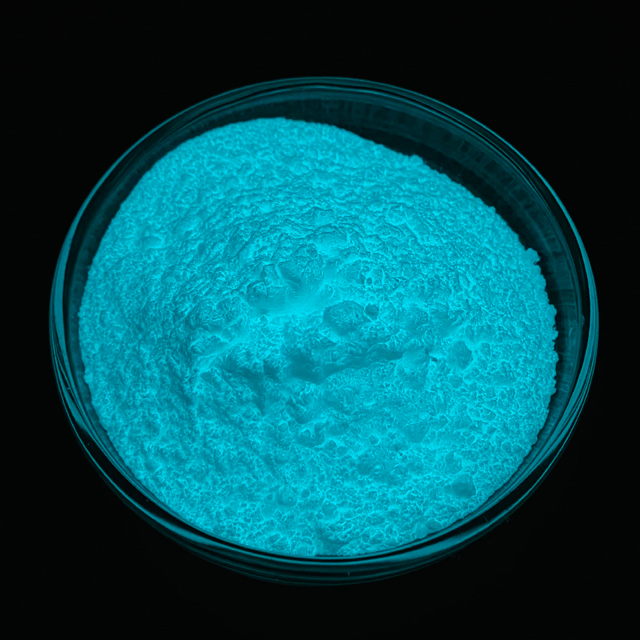

At present, there are many varieties of powder coatings, according to the type of base resin can be divided into: epoxy type, polyester type, polyurethane type, acrylic type and mixed type, etc.; according to its coating film performance can be divided into: indoor coating type, outdoor coating type, outdoor building special type and functional coatings, its wide application areas, such as high temperature resistant coatings, metal effect coatings, glow coatings, fluorocarbon coatings, flame retardant coatings, decorative coatings, fluorescent This paper focuses on glow powder coatings. This paper focuses on the performance index of glow powder coatings and the application of glow pigments in powder coatings.

The factors affecting the performance of glow powder coatings are various, and this paper focuses on the covering power of the coating film. The amount of glow pigments, the thickness of the coating film and the base color of the precoat are the main factors affecting the coverage of the coating film. First of all, the covering power of glow pigments and their amount in the coating formulation is one of the influencing factors. First, the coverage of glow pigments and their amount in the coating formulation is one of the factors that affect.

Secondly, the base color of the pre-painted material must be played on the white This can not only increase the covering power but also enhance the luminous glow. This will not only increase the coverage but also enhance the luminescence. The more glow pigments are added, the more coverage the film will have. However, the physical properties of the coating film will deteriorate, and the cost of powder coating will increase. Generally, instead of increasing the amount of glow pigment to enhance the covering power, it is used to beat on the precoat. Instead of increasing the amount of glow pigments to enhance coverage, a white base is used on the pre-coat to enhance coverage and also The luminous brightness is enhanced.

Through a large number of experiments, the following conclusions: in the preparation of light-emitting powder the choice of raw materials and the combination of components are crucial when formulating luminous powder coatings. The manufacturing process of glow powder coatings is demanding and should be strictly enforced during production. Otherwise, it is easy to produce color difference. In addition, the treatment of the substrate is also indispensable, the best substrate is white, because this can In addition, the treatment of the substrate is also indispensable, the best substrate is white, because this can enhance the luminous glow of the powder coating in the dark.